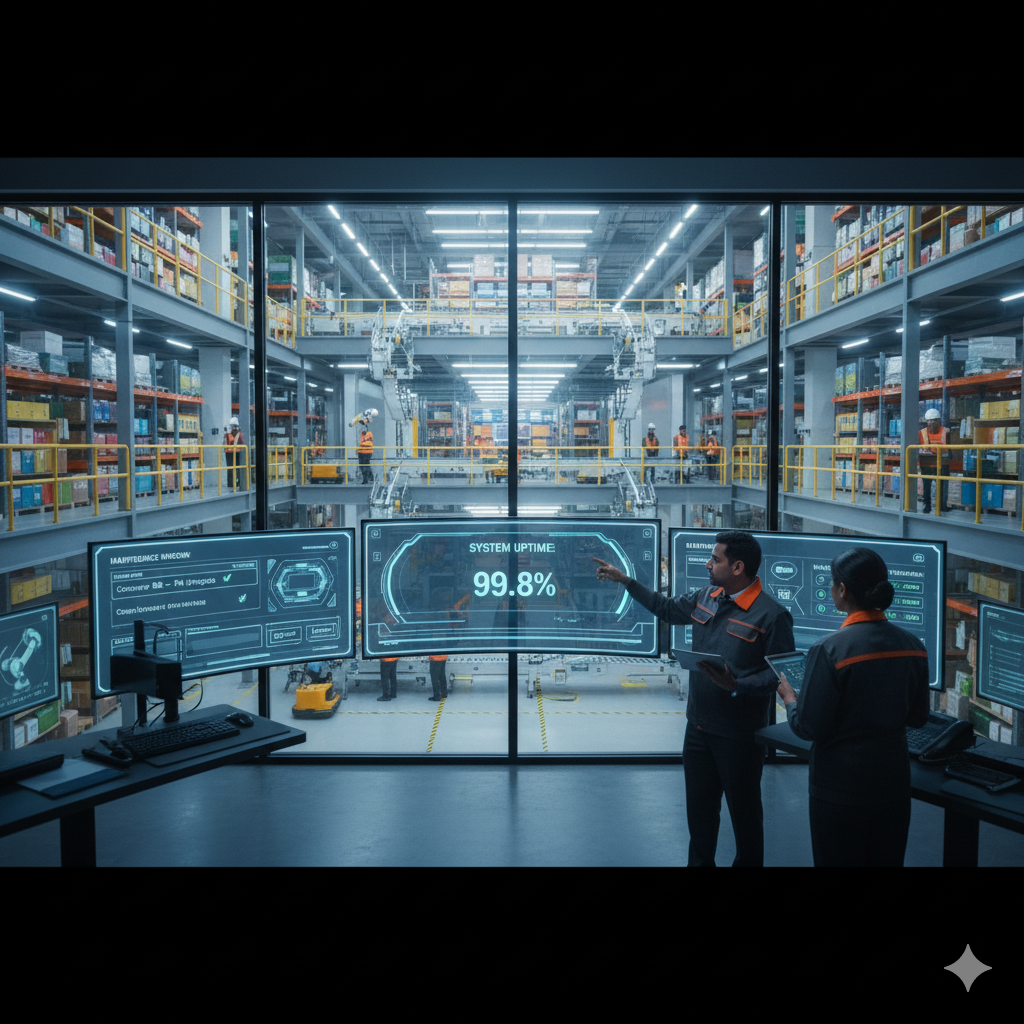

Q: How do we keep urban fulfilment hubs operating at 99% uptime during festival peaks?

By Express HR Solutions on 2025-09-24 19:23:01

With the festive season just weeks away, this is the critical question facing operations leaders across India. In a high-volume urban fulfilment centre, downtime isn't just an inconvenience; it's a catastrophic failure that directly impacts revenue, erodes customer trust, and creates downstream logistical chaos. Every minute a conveyor belt is stopped or a sorting machine is offline costs you money and reputation.

Achieving near-perfect uptime during a 3x order surge isn't about having a single, perfect plan. It's about building a resilient operational framework designed to anticipate and contain failures. Here is the direct, three-part strategy to achieve it.

A: Prioritize cross-trained teams, staged maintenance, and a rapid-response vendor panel.

This framework shifts your facility management from a reactive, break-fix model to a proactive, resilience-focused system.

1. Deploy Cross-Trained 'Facility SWAT Teams'

Your single biggest point of failure is dependency on specialists. During a demand surge, you cannot afford to wait 45 minutes for an electrician to fix a tripped circuit on a critical packing line.

The solution is to build small, agile, on-site teams where members have both primary and secondary skills. Your floor supervisor should be trained in basic conveyor maintenance; your IT support should know how to reboot the server that runs the sorting system. These teams can handle over 80% of common, Tier-1 issues immediately, without escalating.

-

The Challenge: Finding, vetting, and deploying temporary staff with these specific, hybrid skill sets is a significant hurdle. This is where a strategic staffing partner becomes essential, as they can build these multi-skilled teams to your exact specifications.

2. Implement Staged Preventive Maintenance Windows

Shutting down an entire facility for maintenance before a peak season is no longer practical. Instead, implement a rolling schedule of micro-maintenance windows during the lowest-volume hours (e.g., 2 AM - 4 AM).

-

Monday: Preventive maintenance (PM) on conveyor motors in Zone A.

-

Tuesday: PM on sorting scanners in Zone B.

-

Wednesday: PM on packaging machine sensors in Zone C.

This staggered approach ensures your hub is always operating at over 90% capacity. You identify and fix potential issues before they become catastrophic failures, without ever having to shut down the entire operation.

3. Establish a 'Rapid Triage' Vendor Panel

For critical infrastructure—HVAC, main power grids, server arrays—you cannot rely on a single external vendor. They are servicing all their clients during the same peak period.

Build a panel of pre-vetted vendors with strict Service Level Agreements (SLAs).

-

Primary Vendor: On-site response time < 60 minutes.

-

Secondary Vendor: On-site response time < 90 minutes.

The protocol must be automatic. If the primary vendor cannot meet the 60-minute SLA, the call is immediately escalated to the secondary partner. This eliminates negotiation and decision-making delays during a crisis.

Real-Time KPIs for Your Operations Dashboard

To manage this system effectively, your dashboard needs to monitor more than just output. Track these four metrics hourly:

-

Mean Time Between Failures (MTBF): For all critical equipment. A falling MTBF is your number one leading indicator of a future breakdown.

-

Mean Time To Repair (MTTR): The moment an issue is logged, the clock starts. Your goal is to constantly drive this number down. This metric directly proves the value of your cross-trained teams.

-

First-Call Resolution Rate (FCRR): What percentage of facility issues are resolved by your on-site 'SWAT team' without needing an external vendor? A high FCRR (over 80%) is the benchmark for an efficient and resilient operation.

-

Facility Uptime Percentage: The ultimate metric. If this dips below 99% for any given hour, it should trigger an automatic operational review.

Achieving 99% uptime isn't about luck. It's about a disciplined system of versatile people, proactive processes, and redundant support.

The foundation of this entire system is having the right people on the floor. Express HR Solutions specialises in sourcing and deploying the cross-trained facility management teams that keep your operations running at peak capacity.

Let's build your 'Facility SWAT Team' for this festive season.